Introduction to Scalable Manufacturing Solutions

For businesses developing advanced electronics, large-scale production demands precision, efficiency, and strict quality control. High Volume PCB Assembly provides the capability to produce thousands of printed circuit boards with uniform accuracy, ensuring that every unit performs exactly as intended. This approach is ideal for companies looking to meet growing market demands without compromising product reliability.

The Importance of High Volume PCB Assembly in Modern Electronics

With the rapid expansion of consumer electronics, automotive technology, telecommunications, and industrial systems, the need for High Volume PCB Assembly has never been greater. Large-scale manufacturing not only reduces production costs per unit but also ensures consistent results across batches. By relying on advanced automation and expert supervision, manufacturers can meet strict deadlines while maintaining high standards.

Precision and Efficiency in Every Batch

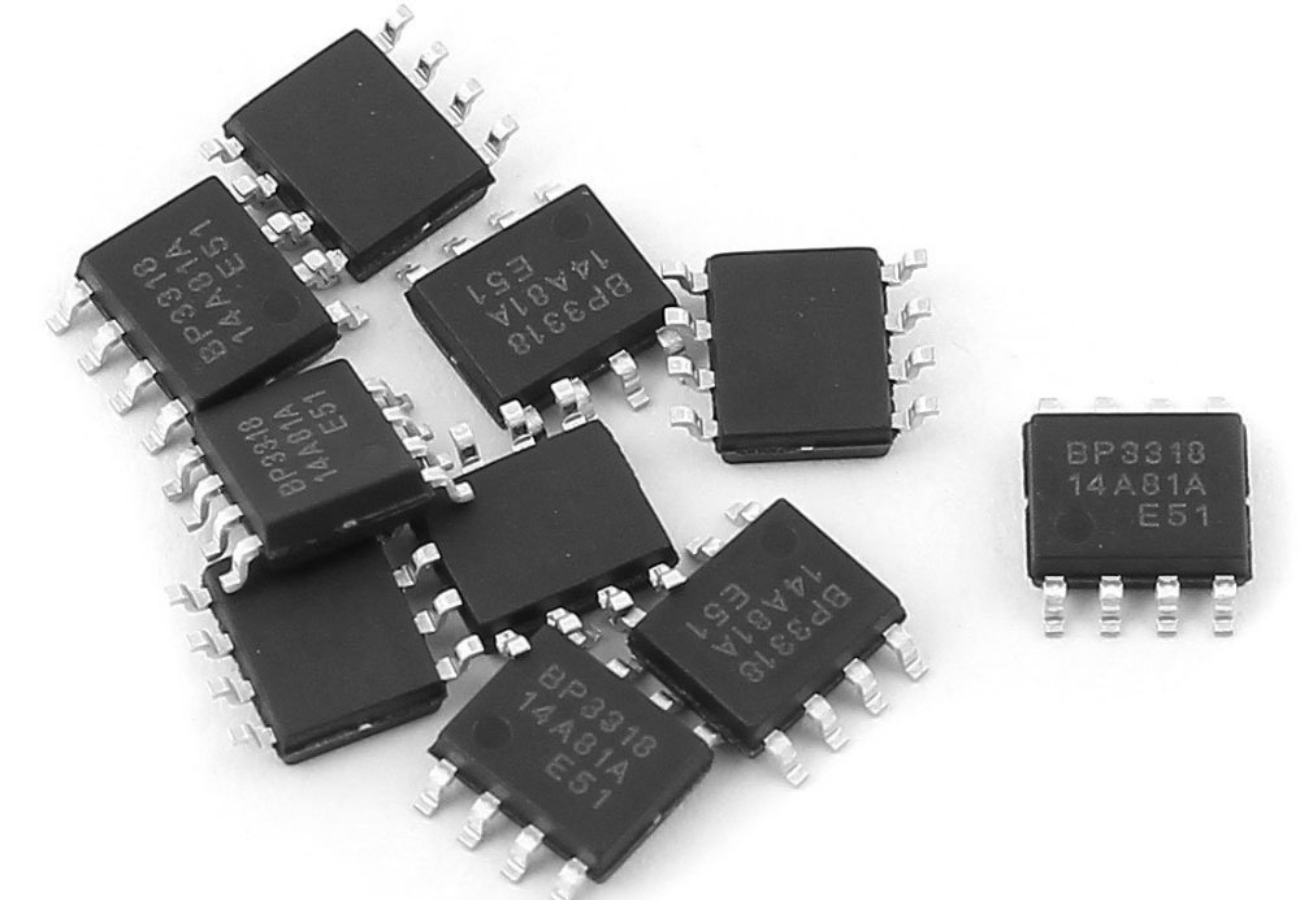

The success of High Volume PCB Assembly depends on streamlined processes and cutting-edge machinery. Automated pick-and-place systems, high-speed soldering lines, and advanced inspection equipment ensure that every component is positioned and connected with flawless accuracy. This level of precision helps reduce defects, improve product lifespan, and enhance overall performance.

Customized Solutions for Diverse Industries

Different industries have unique requirements, and High Volume PCB Assembly can be adapted to meet them. Whether producing boards for high-performance computing devices, medical equipment, or automotive electronics, customization in layout design, materials, and assembly methods ensures that the final product aligns perfectly with the intended application. This flexibility allows companies to respond quickly to changing market needs.

Benefits of Partnering with an Experienced Assembly Provider

Collaborating with a skilled manufacturer specializing in High Volume PCB Assembly offers numerous advantages. These experts understand how to optimize production lines, source quality components, and maintain strict testing standards. Their experience in handling complex designs and large-scale orders ensures that businesses can scale production efficiently without sacrificing quality or reliability.

Advanced Technology Ensuring Consistent Quality

Modern High Volume PCB Assembly facilities rely on sophisticated technologies such as Automated Optical Inspection (AOI), X-ray inspection, and in-circuit testing. These quality control methods detect even the smallest irregularities before boards are shipped, ensuring that each unit meets exact specifications. This combination of automation and expert oversight helps minimize errors and maintain production efficiency.

Streamlined Workflow from Start to Finish

A well-structured High Volume PCB Assembly process begins with careful planning and continues through to final testing and packaging. Manufacturers manage the entire workflow, including design validation, component procurement, assembly, and quality assurance. This seamless approach not only speeds up production but also ensures consistency across every batch of circuit boards.

Conclusion – Driving Growth Through Reliable Mass Production

In a competitive electronics market, High Volume PCB Assembly enables companies to deliver products at scale without compromising quality. By combining advanced technology, skilled expertise, and efficient processes, these services support innovation while meeting the high demands of global production. For businesses aiming to expand their reach and deliver dependable electronic solutions, high-volume manufacturing remains the key to sustained success.