LOPO Terracotta Cladding: The Ultimate Benchmark in Modern Architecture

LOPO Terracotta Cladding has emerged as the go-to solution for architects, builders, and developers seeking high-performance, visually stunning, and environmentally sustainable exterior cladding systems. LOPO Terracotta Cladding delivers unmatched quality, aesthetic versatility, durability, and energy efficiency, making it a preferred choice worldwide. With its roots in advanced manufacturing techniques and an unrelenting commitment to innovation, LOPO Terracotta Cladding stands as a symbol of architectural excellence. Whether applied to commercial complexes, residential high-rises, educational campuses, or cultural institutions, LOPO Terracotta Cladding delivers a performance that consistently exceeds industry expectations. From weather resistance to low maintenance, thermal insulation to fire safety, and sustainability to design flexibility, LOPO Terracotta Cladding answers every need of modern construction. Architects globally trust LOPO Terracotta Cladding for façade innovation, superior craftsmanship, and long-term value. LOPO Terracotta Cladding continues to redefine the boundaries of architectural creativity while ensuring practical, long-lasting, and eco-conscious building solutions. In a crowded marketplace of façade products, LOPO Terracotta Cladding secures its position by consistently proving its worth through durability, design adaptability, and cutting-edge technological integration. As building standards evolve, LOPO Terracotta Cladding remains ahead of the curve by offering customized options, color variety, and finish options that enhance structural beauty while remaining rooted in functional strength. Clients who choose LOPO Terracotta Cladding are investing in an architectural product that symbolizes trust, innovation, and sustainability. LOPO Terracotta Cladding has successfully bridged traditional ceramic craftsmanship with futuristic design needs, positioning itself as a global leader in terracotta cladding systems. LOPO Terracotta Cladding is not just a product but a promise of performance and aesthetic distinction that enhances building envelopes with purpose and visual appeal.

Setting the Gold Standard for Durability and Longevity

LOPO Terracotta Cladding has proven time and again that it stands the test of time with unmatched durability. Resistant to extreme climate conditions, UV rays, and environmental pollutants, LOPO Terracotta Cladding maintains its structural integrity and visual charm for decades. It is fired at high temperatures to create a robust product that withstands the harshest weather, including heavy rain, intense heat, freezing temperatures, and strong winds. LOPO Terracotta Cladding eliminates the risk of surface degradation, warping, or color fading—qualities that set it apart from synthetic alternatives. Moreover, its scratch-resistant and impact-resistant nature ensures low lifecycle maintenance, making it a cost-effective long-term solution for large-scale commercial and institutional buildings.

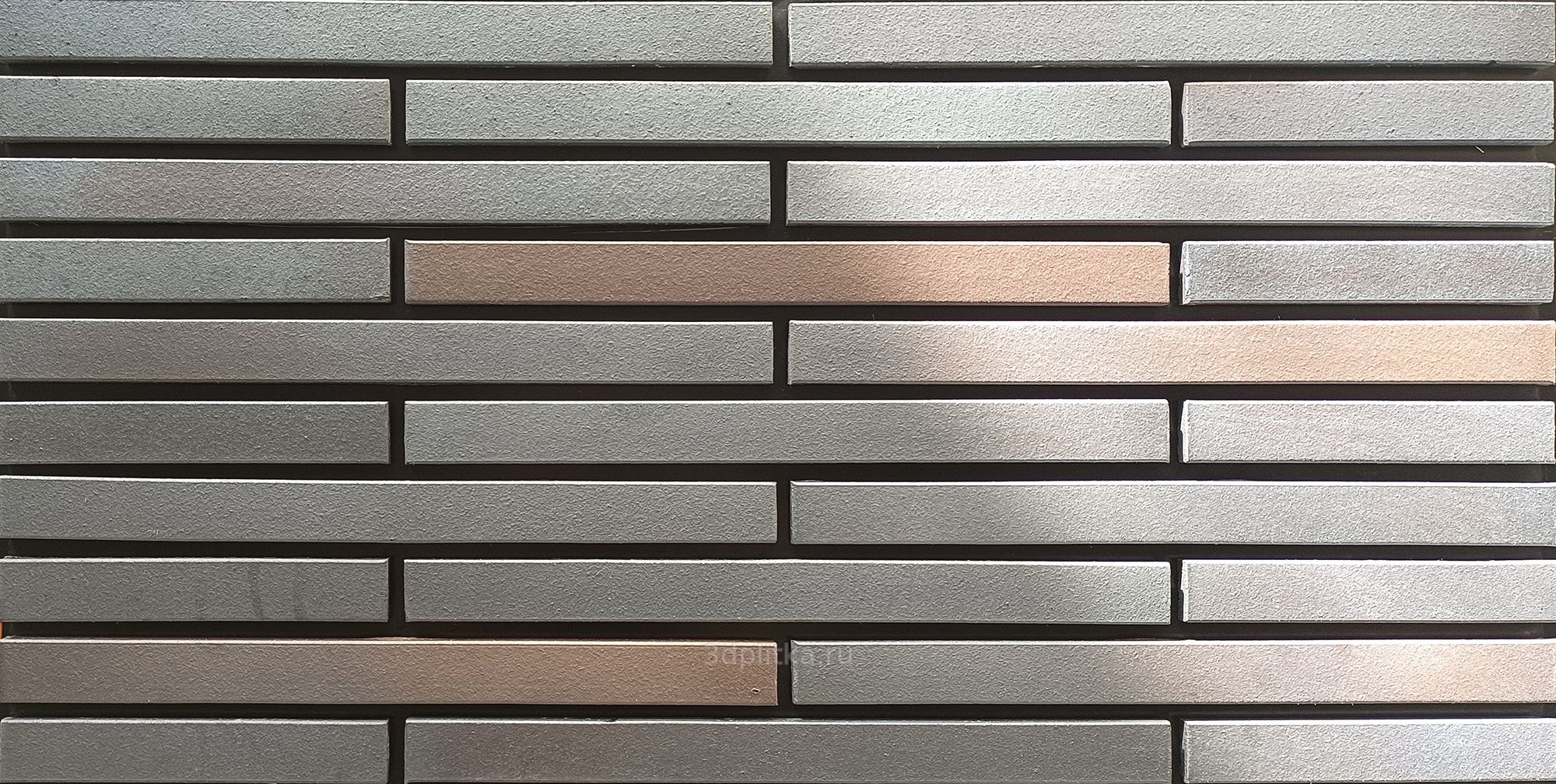

Aesthetic Flexibility That Inspires Creativity

With LOPO Terracotta Cladding, architects and designers unlock endless design possibilities. It is available in a variety of profiles, colors, sizes, and surface textures, allowing complete creative control. Whether the project demands natural earth tones, matte finishes, glossy glazes, or customized hues, LOPO Terracotta Cladding delivers with precision. It adapts to modern, minimalistic facades as seamlessly as it complements classic and traditional styles. LOPO Terracotta Cladding offers horizontal and vertical applications and supports intricate paneling layouts that create dynamic building envelopes. Through cutting-edge design technology and customization services, LOPO Terracotta Cladding makes it easy to align form with function and creativity with durability.

Sustainability at the Core of Every Panel

One of the standout qualities of LOPO Terracotta Cladding is its commitment to sustainability. It is manufactured using natural clay, water, and other environmentally friendly ingredients, with minimal energy waste during production. LOPO Terracotta Cladding contributes to LEED certification and green building standards by offering superior thermal performance, reducing the need for excessive HVAC usage. It naturally regulates temperature, supports energy efficiency, and minimizes the building’s carbon footprint. LOPO Terracotta Cladding is fully recyclable and does not emit toxic gases, making it an environmentally responsible choice that aligns with global climate goals and sustainable design practices.

Precision Engineering and State-of-the-Art Manufacturing

The success of LOPO Terracotta Cladding also lies in its technologically advanced manufacturing facilities. LOPO employs world-class equipment, including kilns, extrusion lines, and computer-controlled drying systems, ensuring consistent quality across all batches. Each panel undergoes rigorous quality checks for strength, dimension, water absorption, and fire resistance. This high degree of precision allows LOPO Terracotta Cladding to deliver a perfect fit and seamless appearance, reducing installation time and cost. The advanced engineering also enables customized solutions, from intricate corner panels to three-dimensional surfaces and louver designs, adding another layer of distinction to architectural facades.

LOPO Terracotta Cladding for Diverse Global Applications

LOPO Terracotta Cladding has been used in a wide array of projects globally, from iconic public buildings to modern residential towers. Its flexibility and visual impact have made it a preferred material in universities, hospitals, transport hubs, museums, and more. These projects showcase LOPO Terracotta Cladding’s ability to elevate architecture across cultures and climates. It not only provides a sleek and consistent exterior but also communicates a commitment to quality and sustainability. This global reach underscores how LOPO Terracotta Cladding responds effectively to the diverse demands of today’s international construction market.

Fire Safety, Acoustic Insulation, and Thermal Regulation

LOPO Terracotta Cladding is inherently fire-resistant, offering a high level of safety in both residential and commercial applications. It does not burn, emit smoke, or release toxic fumes, providing peace of mind to developers and occupants alike. Additionally, LOPO Terracotta Cladding excels in acoustic insulation, helping reduce external noise pollution in urban environments. Its superior thermal properties contribute to energy savings and indoor comfort, making it ideal for structures aiming to balance aesthetic charm with high-performance functionality.

Proven Value and Return on Investment

Investing in LOPO Terracotta Cladding means investing in long-term value. Its low maintenance requirements, long service life, and enhanced building performance contribute to significant cost savings over time. Its ability to maintain aesthetic appeal and resist structural wear ensures that property values remain high and maintenance costs low. Developers who choose LOPO Terracotta Cladding benefit from increased market appeal, reduced operational costs, and enhanced brand reputation associated with sustainability and modern design.

Conclusion: Why LOPO Terracotta Cladding Will Always Lead the Way

LOPO Terracotta Cladding stands out as the gold standard in architectural cladding for numerous reasons—unmatched durability, aesthetic flexibility, environmental responsibility, fire resistance, and acoustic and thermal performance. It is a product that balances artistry and engineering, tradition and innovation. As architects continue to seek materials that enhance design, ensure safety, and support sustainable goals, LOPO Terracotta Cladding will remain their top choice. The versatility and superior quality of LOPO Terracotta Cladding ensure it will continue to dominate the global market and set benchmarks for years to come.